Galvanized steel coil and galvalume steel coil are two different types of steel coils, each with its own characteristics and applications:

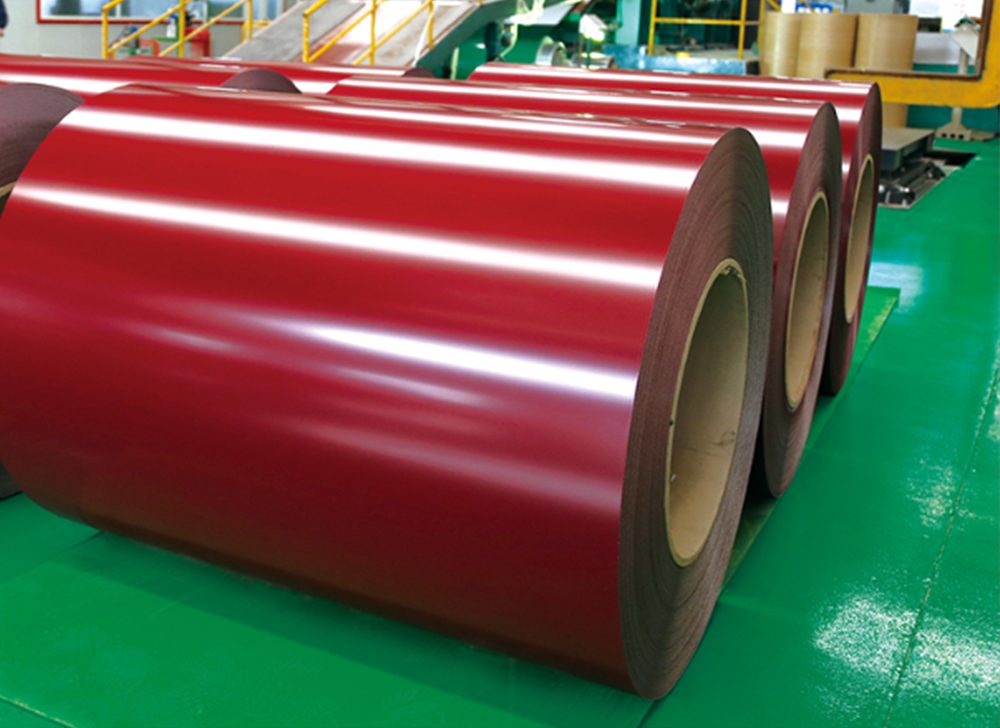

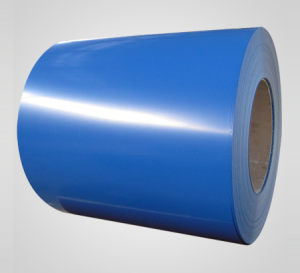

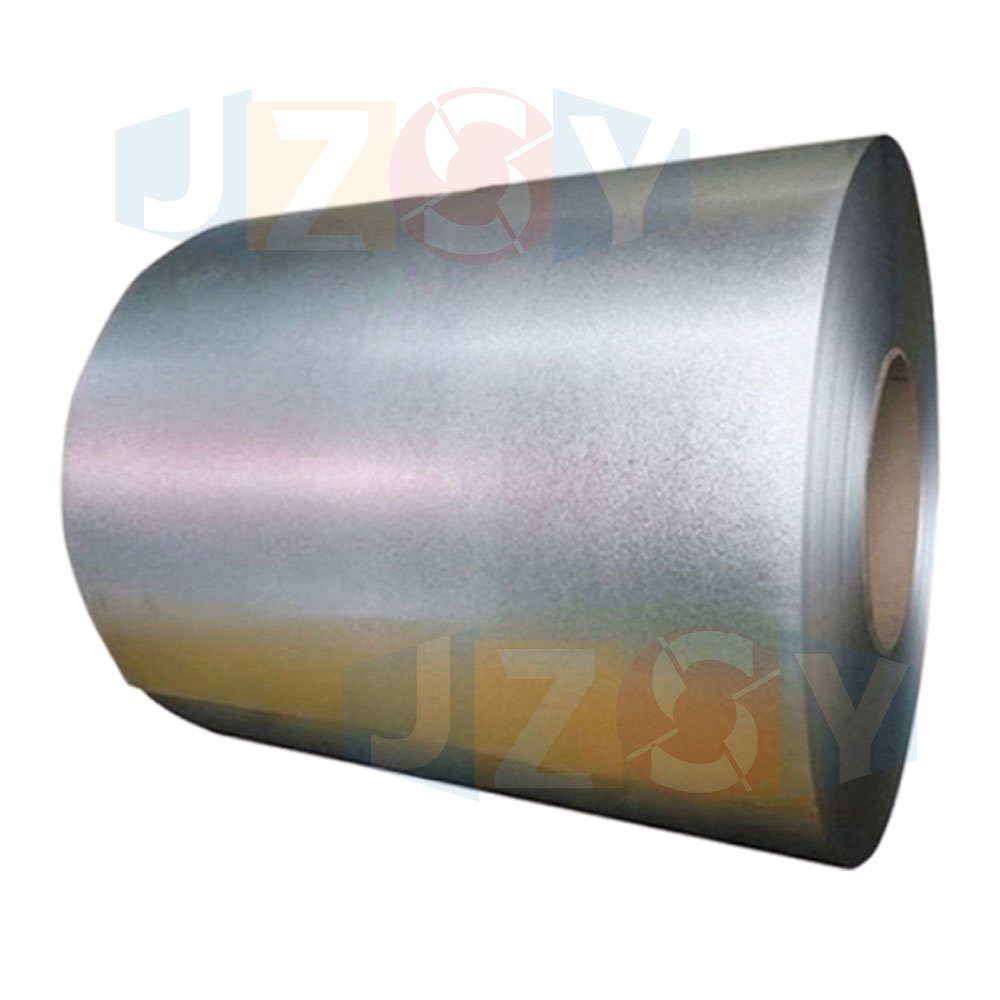

Galvanized Steel Coil:

- Characteristics: Galvanized steel coil refers to a steel coil that has been coated with a layer of zinc on its surface to enhance its corrosion resistance. Galvanized steel coil is typically produced using a hot-dip galvanizing process, where the steel is immersed in molten zinc to apply the coating.

- Applications: Due to its excellent corrosion resistance, galvanized steel coil is widely used in construction, appliances, automotive manufacturing, etc., particularly in environments that are exposed to moisture or acidic conditions.

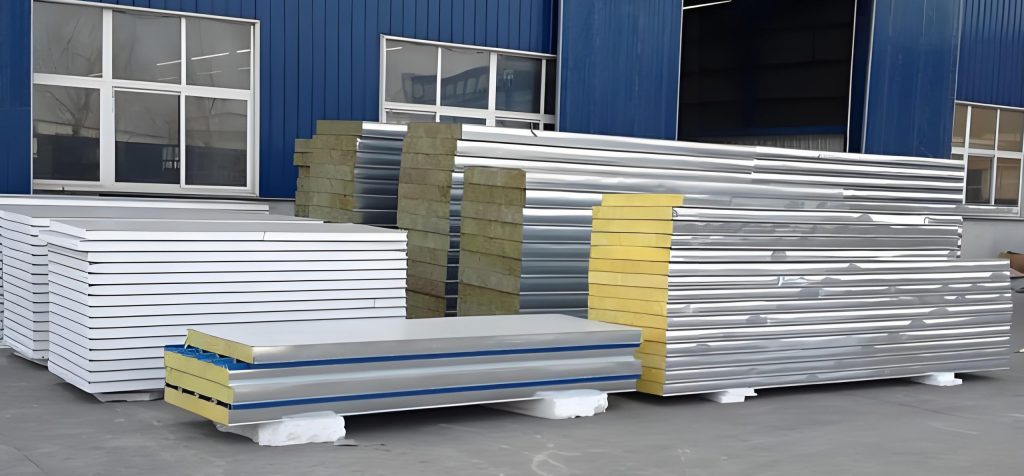

Galvalume Steel Coil:

- Characteristics: Galvalume steel coil refers to a steel coil that has been coated with a layer of aluminum and zinc alloy on its surface to improve its corrosion resistance and weatherability. This coating enhances the steel’s resistance to oxidation and corrosion.

- Applications: Galvalume steel coil is commonly used in more demanding applications such as roofing, wall cladding, facade systems, where higher weather resistance and aesthetic requirements are needed.

In summary, both galvanized steel coil and galvalume steel coil are important for enhancing the corrosion resistance of steel, and the choice between them depends on specific usage environments and requirements.