In steel manufacturing, coating materials play a vital role. Among them, PPGI, PPGL and PPGF are very common types. They differ in composition, performance and application scenarios, so they are worthy of our in-depth understanding.

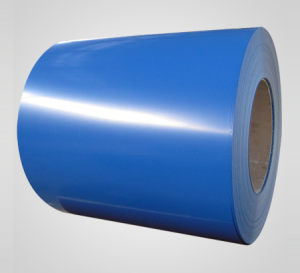

PPGI (pre-painted galvanized steel):

- It is a product with a zinc layer on the surface of the steel plate.

- This coating can provide good corrosion resistance, protect the steel plate from atmospheric corrosion and extend its service life.

- PPGI is commonly used in construction, home appliances, automobiles and other fields.

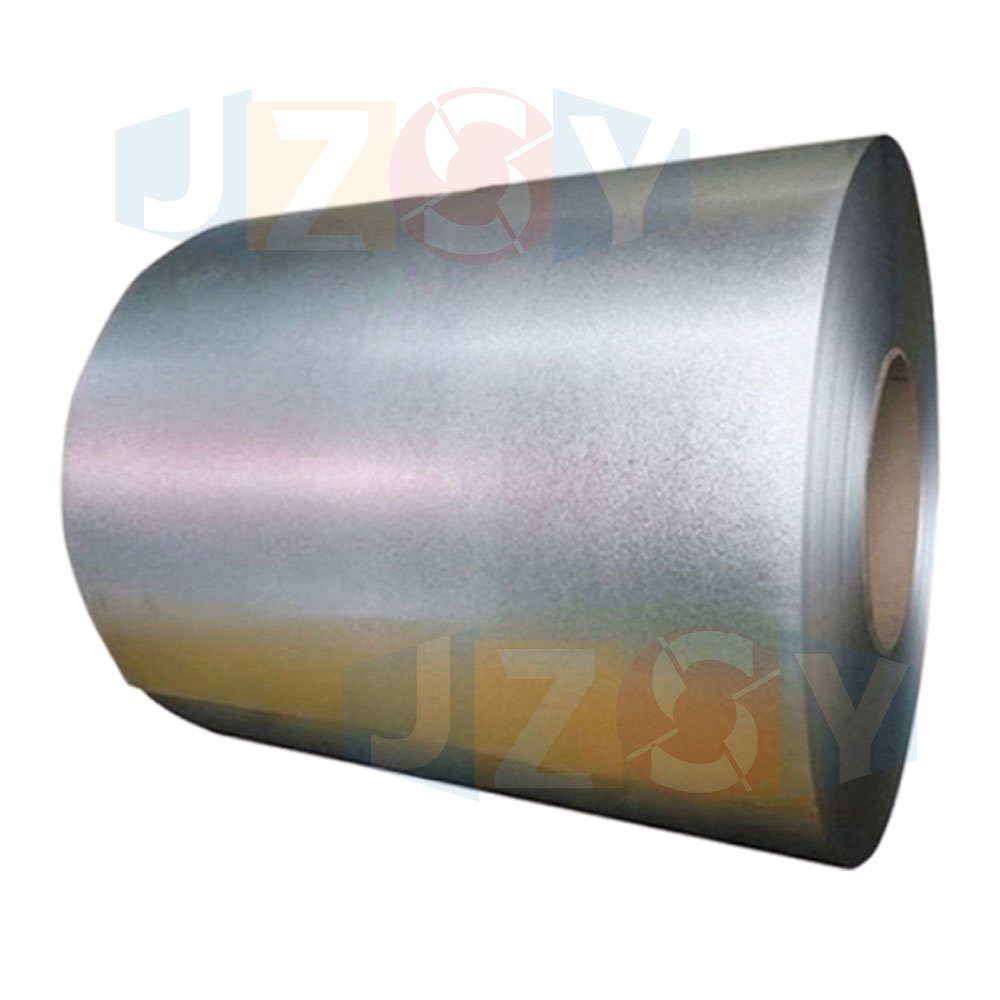

PPGL (pre-coated galvalume steel sheet):

- Similar to PPGI, PPGL is also a product coated with a zinc alloy layer on the surface of the steel plate, but unlike PPGI, its coating contains not only zinc but also aluminum.

- This gives PPGL better corrosion resistance and longer service life, making it suitable for harsher environmental conditions.

PPGF (Precoated Glass Fiber Reinforced Plastic):

- Unlike the first two, PPGF is a plastic material reinforced with glass fiber rather than steel plate.

- This material has excellent strength and corrosion resistance and is often used to manufacture ships, storage tanks, wind turbine blades and other products that require lightweight and high strength.